MetaPro

Professional

Services

- Project Estimation

- Project Status Tracking

- Prospect Identification

- Complete Project Cost Visibility

- Resource Allocation

MetaDocs

Document Management System

- Drag & Drop documents from Outlook

- Document Storage

- Document Search

- Document Accessibility

- Seamless Integrations

- Document Sharing

- Disaster Recovery

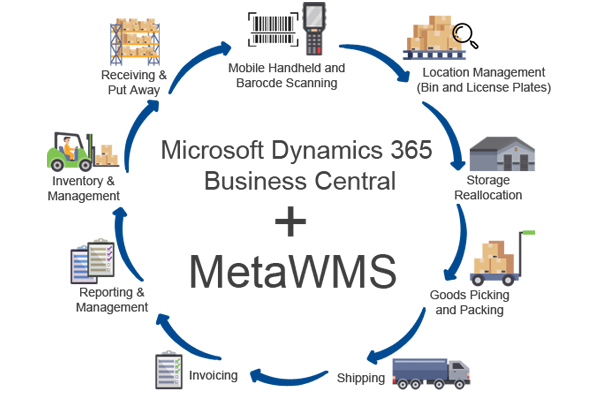

MetaWMS

Advanced Warehouse Management System

- Bin

- License Plating

- 1D/2D Barcode and Label Printing

- Put Away and Pick

- Cycle Counting

- Warehouse Receipt and Shipping

- Shipping with Integration to Multiple Carriers

MetaShip

Packing and Shipping Solution

- Order Processing

- Shipment Tracking

- Carrier Integration

- Shipping Label Generation

- Multi-Carrier Support

- Rate Shopping

- Address Validation

- Return Management

- Warehouse Integration

- Reporting and Analytics